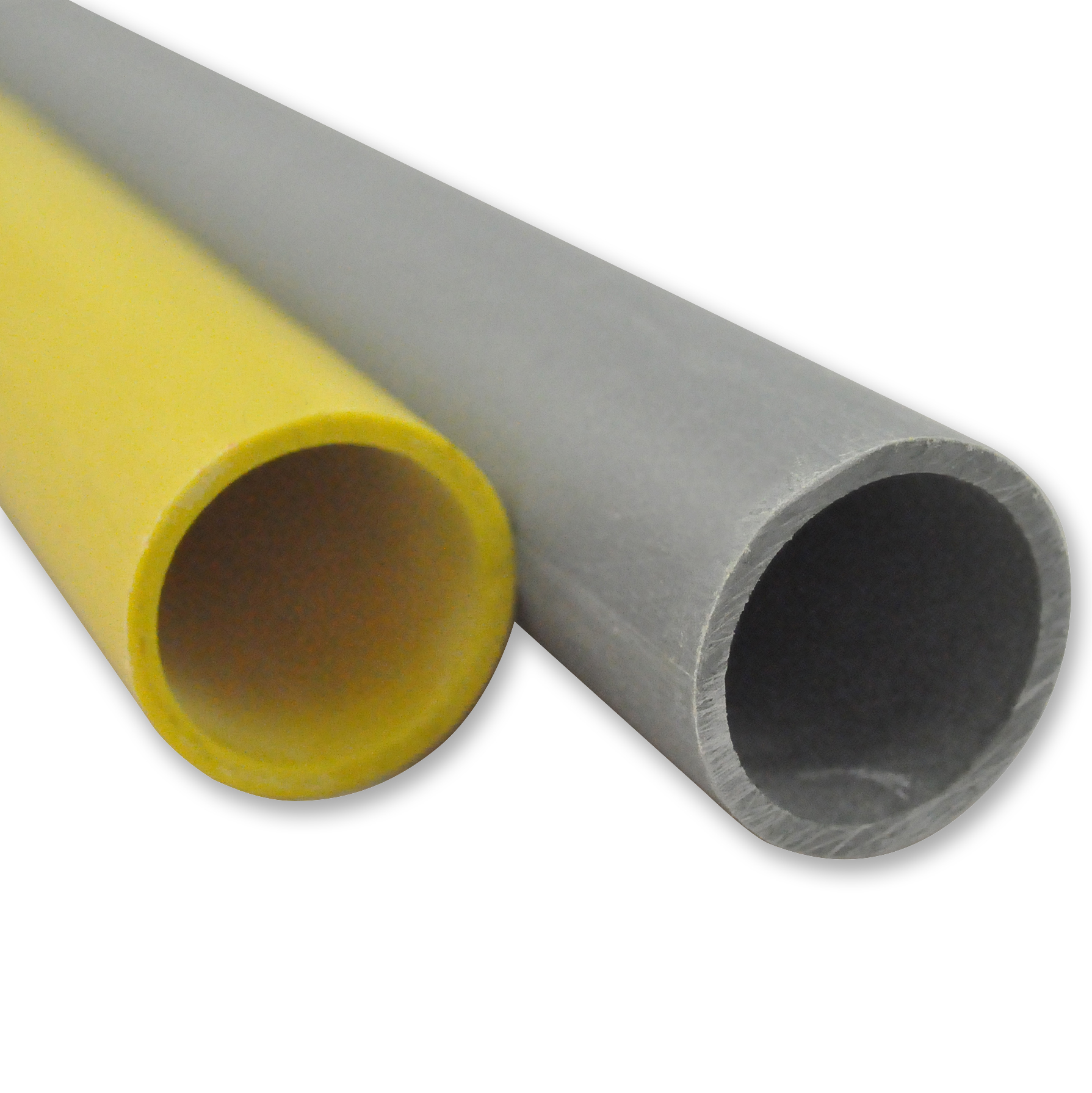

Description

GRP Tube Profiles are created by the pultrusion process and has high glass content and excellent mechanical properties. Each profile has a barrier built in that makes it resistant to both corrosion and weathering. This ensures the structural profile has maximum long-term performance in all environments. They come stocked 6000mm lengths, but we do offer a cutting service – for details click here.

Each profile has many benefits to it, including:

- Exceptional strength: pultruded profiles are stronger than steel, and the high impact strength of GRP reduces any damage that may be caused by accidental collisions

- Lightweight: GRP tube profiles weigh 80% less than its steel counterparts and 30% less than aluminium. Even though there is less weight, the profiles provide a performance that is at an equivalent level

- Corrosion resistant: although GRP is usually unaffected by exposure to chemicals and environments, they still have an added synthetic surface veil, which provides the profile with a resin rich layer which ultimately enhances the already excellent corrosion resistant properties

- Maintenance free: the added corrosion resistant properties of FRP profiles remove the need for regular painting or surface treatment

- Low thermal conductivity: all GRP tube profiles have low thermal conductivity. They are around 1/250 of aluminium, and 1/60 of steel

- Non-conductive: GRP Profiles are electrically non-conductive. This makes their specification ideal for cable trays, ladders, cover boards, etc.

- Electromagnetic transparency: GRP is transparent to a range of electromagnetic frequencies which makes it ideal for aerial masts and radar applications.

- Dimensional stability: GRP is resistant to all kinds of stretching, warping or swelling over a variety of temperatures and physical stresses

- Thermal stability: these profiles are able to withstand exposure to temperatures of up to 65 degrees Celsius

We offer a range of other GRP Profiles. These include I-Beam, H-Beam, C-Section, Box and Angle.